Sensing, Actuation, and Control of the SmartX Prototype Morphing Wing in the Wind Tunnel

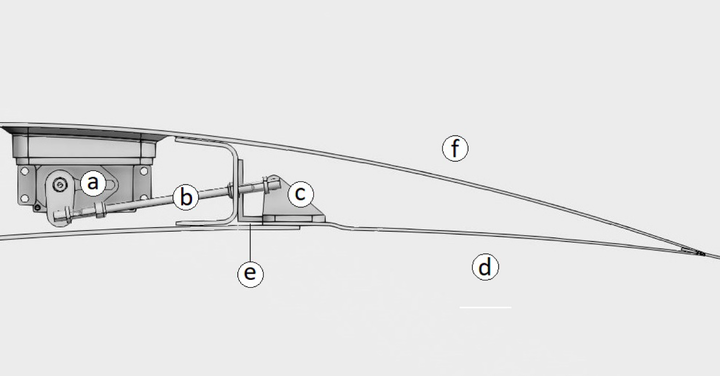

Cross-sectional view of the module showing the internal setup and morphing mechanism.

Cross-sectional view of the module showing the internal setup and morphing mechanism.

Abstract

This paper presents a study on trailing edge deflection estimation for the SmartX camber morphing wing demonstrator. This demonstrator integrates the technologies of smart sensing, smart actuation and smart controls using a six module distributed morphing concept. The morphing sequence is brought about by two actuators present at both ends of each of the morphing modules. The deflection estimation is carried out by interrogating optical fibers that are bonded on to the wing’s inner surface. A novel application is demonstrated using this method that utilizes the least amount of sensors for load monitoring purposes. The fiber optic sensor data is used to measure the deflections of the modules in the wind tunnel using a multi-modal fiber optic sensing approach and is compared to the deflections estimated by the actuators. Each module is probed by single-mode optical fibers that contain just four grating sensors and consider both bending and torsional deformations. The fiber optic method in this work combines the principles of hybrid interferometry and FBG spectral sensing. The analysis involves an initial calibration procedure outside the wind tunnel followed by experimental testing in the wind tunnel. This method is shown to experimentally achieve an accuracy of 2.8 mm deflection with an error of 9%. The error sources, including actuator dynamics, random errors, and nonlinear mechanical backlash, are identified and discussed.